E-mail: ttwoodgaslimited@gmail.com

E-mail: ttwoodgaslimited@gmail.com

E-mail: ttwoodgaslimited@gmail.com

E-mail: ttwoodgaslimited@gmail.com

T&T Woodgas Ltd is a company that specializes in providing sustainable green fuel for clean cooking energy. Our products include woodgas and briquettes, which are both eco-friendly alternatives to traditional fossil fuels. Woodgas is produced through a process called wood gasification, which converts wood into a gas that can be used for heating and cooking. Briquettes, on the other hand, are made from compressed carbonised sawdust and other woodwastes materials, and are an efficient and clean-burning fuel source.

T&T Woodgas Ltd is committed to creating sustainable solutions for energy production that are both environmentally friendly and cost-effective. We are dedicated to reducing the use of fossil fuels and promoting the use of renewable energy sources. Our woodgas and briquettes are ideal for households, businesses, and communities that are looking for sustainable and clean energy solutions. Additionally, T&T Woodgas Ltd has been recognized for our innovative approach to renewable energy and for their commitment to creating a more sustainable future.

Our innovative woodgas technology has been recognized for its contribution to sustainable energy...

Read More

We're excited to announce our latest initiative bringing clean cooking energy to rural communities...

Read More

Our new partnership aims to further improve woodgas technology efficiency and applications...

Read More

Our woodgas generators providing electricity to a remote village, improving quality of life for over 500 residents.

View Project

T&T briquettes powering a sustainable heating system for a large-scale greenhouse operation, reducing carbon emissions by 60%.

View Project

Implementation of woodgas cooking systems in 50 schools, providing clean, efficient energy for meal preparation.

View Project

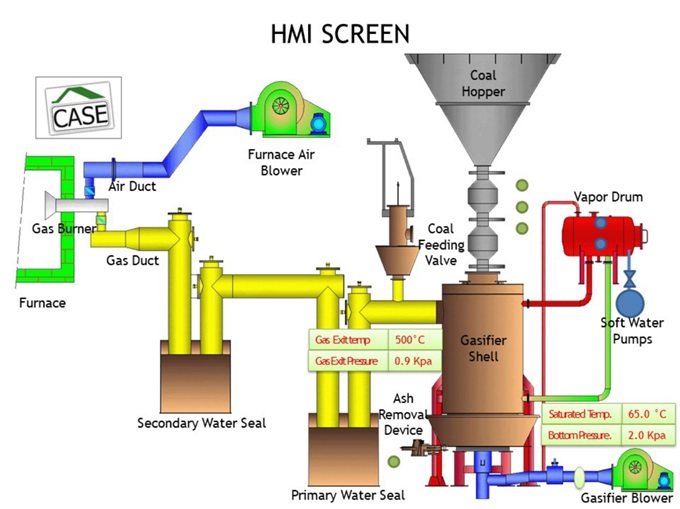

This gasifier features both simple air gasification technology for small power equipment and complex absolute oxygen gasification technology for large power equipment. With power ranging from 50KW to 8000KW, our gasifier can convert a variety of materials into clean gaseous fuel and biochar.

| Model | BGC50 | BGC100 | BGC150 |

|---|---|---|---|

| Fuel Type | Agricultural waste, animal residue, biological waste, sludge | Agricultural waste, animal residue, biological waste, sludge | Agricultural waste, animal residue, biological waste, sludge |

| Raw material granularity | 30~60mm | 30~60mm | 30~60mm |

| Moisture content | 10 – 12 % | 10 – 12 % | 10 – 12 % |

| Low heating value (LHV) | > 4 kWh/kg | > 4 kWh/kg | > 4 kWh/kg |

| Feed quality | 45-55Kg/h | 135-155Kg/h | 135-155Kg/h |

| Gasification intensity | 150~220kg/m2h | 150~220kg/m2h | 150~220kg/m2h |

| Gasification rate of dry material | 1.5~2.5Nm3/kg | 1.5~2.5Nm3/kg | 1.5~2.5Nm3/kg |

| Biogas calorific value | 1000~1200kcal/Nm³ | 1000~1200kcal/Nm³ | 1000~1200kcal/Nm³ |

| Air consumption rate | 2.5Nm3/kg raw material | 2.5Nm3/kg raw material | 2.5Nm3/kg raw material |

| Syngas Composition | |||

| CO | 19-22% | 19-22% | 19-22% |

| H2 | 15-18% | 15-18% | 15-18% |

| CH4 | 1-4% | 1-4% | 1-4% |

| CO2 | 9-12% | 9-12% | 9-12% |

| N2 | 49-53% | 49-53% | 49-53% |

| O2 | 0.1-1% | 0.1-1% | 0.1-1% |

| Syngas Performance | |||

| Flow | 90-115Nm3/h | 130-200Nm3/h | 130-200Nm3/h |

| Calorific value | 5MJ/Nm³ | 5MJ/Nm³ | 5MJ/Nm³ |

| Pressure | 5KPa | 5KPa | 5KPa |

| Residual Ash | |||

| Particle size distribution (< 5 mm) | 64% | 64% | 64% |

| Particle size distribution (< 2 mm) | 35% | 35% | 35% |

| Particle size distribution (< 0.5 mm) | 15% | 15% | 15% |

| Total carbon content | 68.4 | 68.4 | 68.4 |

| Ash | 6.4 | 6.4 | 6.4 |